What is 3D printing?

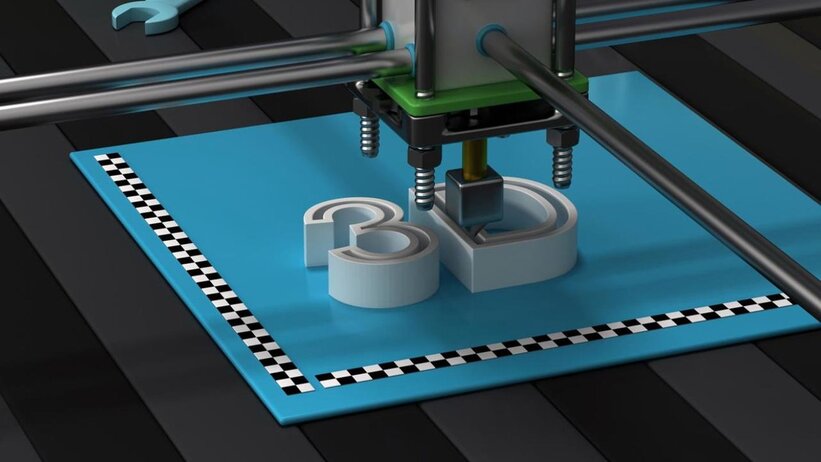

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

How Does 3D printing work?

The 3D printing process turns a whole object into thousands of tiny little slices, then makes it from the bottom-up, slice by slice. Those tiny layers stick together to form a solid object. Each layer can be very complex, meaning 3D printers can create moving parts like hinges and wheels as part of the same object.

3D printers add material, layer-by-layer, to form a 3D object. Virtually any geometry can be 3D printed, including some that cannot be made with other traditional processes.

The 3D printing process turns a whole object into thousands of tiny little slices, then makes it from the bottom-up, slice by slice. Those tiny layers stick together to form a solid object. Each layer can be very complex, meaning 3D printers can create moving parts like hinges and wheels as part of the same object.

3D printers add material, layer-by-layer, to form a 3D object. Virtually any geometry can be 3D printed, including some that cannot be made with other traditional processes.

Since the advent of 3D printing, it has attracted a lot of public attention. This new manufacturing method is not only very creative, but will also have a profound impact in most manufacturing-related industries.

3D printing not only plays an active role in environmental protection, reducing raw material waste, etc. More importantly, its requirements for mass production in the manufacturing industry are very low. For example, the production of a set of abrasive tools in the traditional way often undergoes a relatively complicated process, and the requirements for technical personnel are also relatively high.

This leads to, for example, in the field of machinery manufacturing, sometimes the price of a set of molds is comparable to gold. Then this kind of product, if it is not a special field such as aviation, often has to achieve a certain mass production to have production momentum. The 3D printing technology just makes up for the shortcomings of the manufacturing industry. People can focus more on R&D, which will undoubtedly bring a huge impetus to the personalization and diversification of the manufacturing industry.

When human thinking is less and less affected by the limited manufacturing capacity, 3D printers will eventually become one of the must-have items. Not only that, it may also bring huge changes to certain industries or our lives. Imagine if we are going to build a 3D printed house, do we need to buy water pipes for it to lay? The possible way is probably to leave some metal voids when printing on the wall, so what changes will the traditional construction industry face?

Human beings have created technology, and human beings are surrounded by technology. No matter how much you love tradition, as long as humanity's enthusiasm for exploring the future does not diminish, we will one day say goodbye to tradition.

3D printing not only plays an active role in environmental protection, reducing raw material waste, etc. More importantly, its requirements for mass production in the manufacturing industry are very low. For example, the production of a set of abrasive tools in the traditional way often undergoes a relatively complicated process, and the requirements for technical personnel are also relatively high.

This leads to, for example, in the field of machinery manufacturing, sometimes the price of a set of molds is comparable to gold. Then this kind of product, if it is not a special field such as aviation, often has to achieve a certain mass production to have production momentum. The 3D printing technology just makes up for the shortcomings of the manufacturing industry. People can focus more on R&D, which will undoubtedly bring a huge impetus to the personalization and diversification of the manufacturing industry.

When human thinking is less and less affected by the limited manufacturing capacity, 3D printers will eventually become one of the must-have items. Not only that, it may also bring huge changes to certain industries or our lives. Imagine if we are going to build a 3D printed house, do we need to buy water pipes for it to lay? The possible way is probably to leave some metal voids when printing on the wall, so what changes will the traditional construction industry face?

Human beings have created technology, and human beings are surrounded by technology. No matter how much you love tradition, as long as humanity's enthusiasm for exploring the future does not diminish, we will one day say goodbye to tradition.

Sources:

https://en.wikipedia.org/wiki/3D_printing

https://all3dp.com/2/what-is-a-3d-printing-machine/

https://3dprinting.com/what-is-3d-printing/

https://www.independent.co.uk/life-style/gadgets-and-tech/features/3d-printing-for-dummies-how-do-3d-printers-work-8668937.html

https://en.wikipedia.org/wiki/3D_printing

https://all3dp.com/2/what-is-a-3d-printing-machine/

https://3dprinting.com/what-is-3d-printing/

https://www.independent.co.uk/life-style/gadgets-and-tech/features/3d-printing-for-dummies-how-do-3d-printers-work-8668937.html